ASM Makerspace

2022

Tangents

Project Team: Saad Boujane & Mark Philip

Location: Marrakech, Morocco

Site Area: 250 m²

Built-up Area: 500 m²

Project Team: Saad Boujane & Mark Philip

Location: Marrakech, Morocco

Site Area: 250 m²

Built-up Area: 500 m²

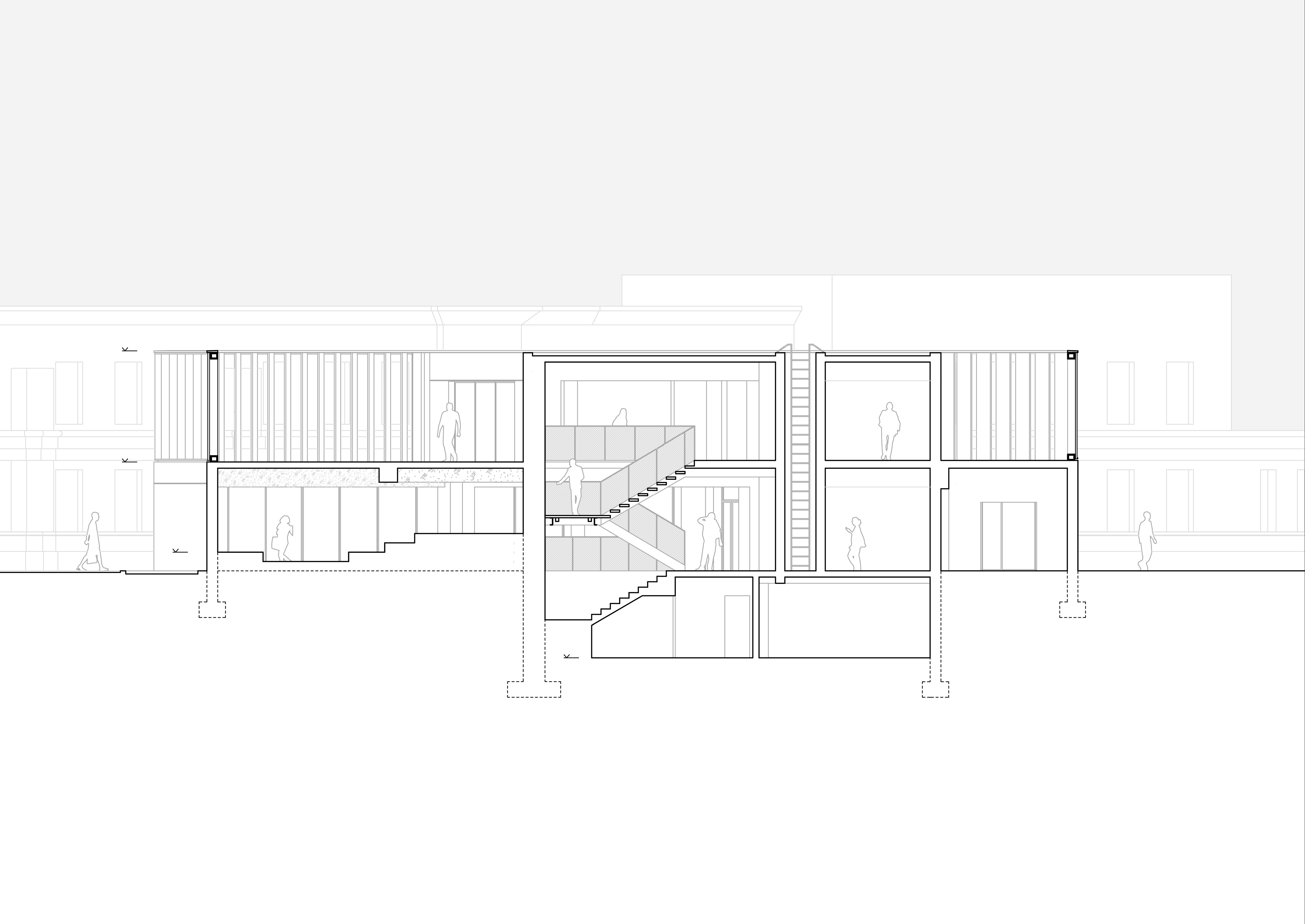

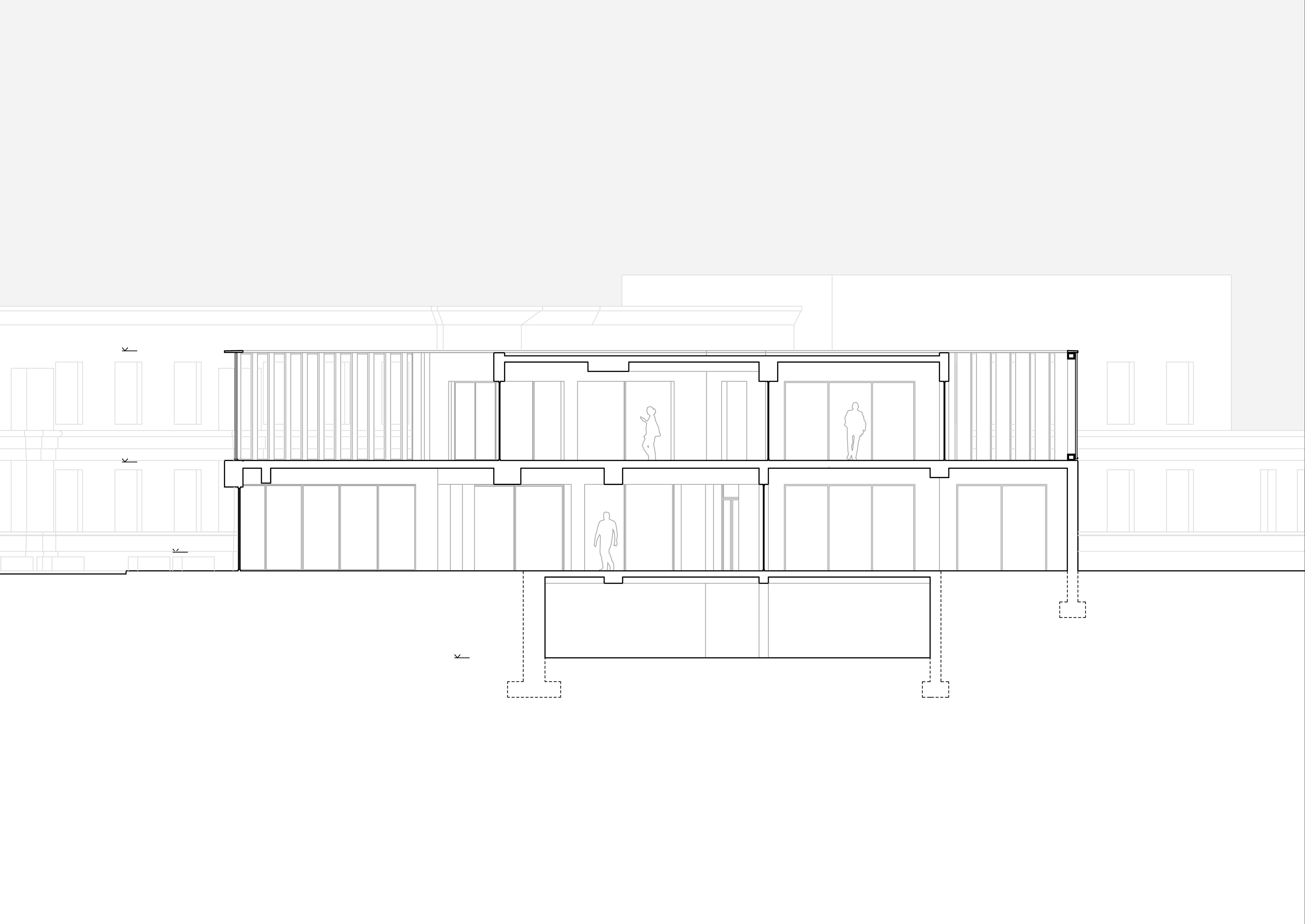

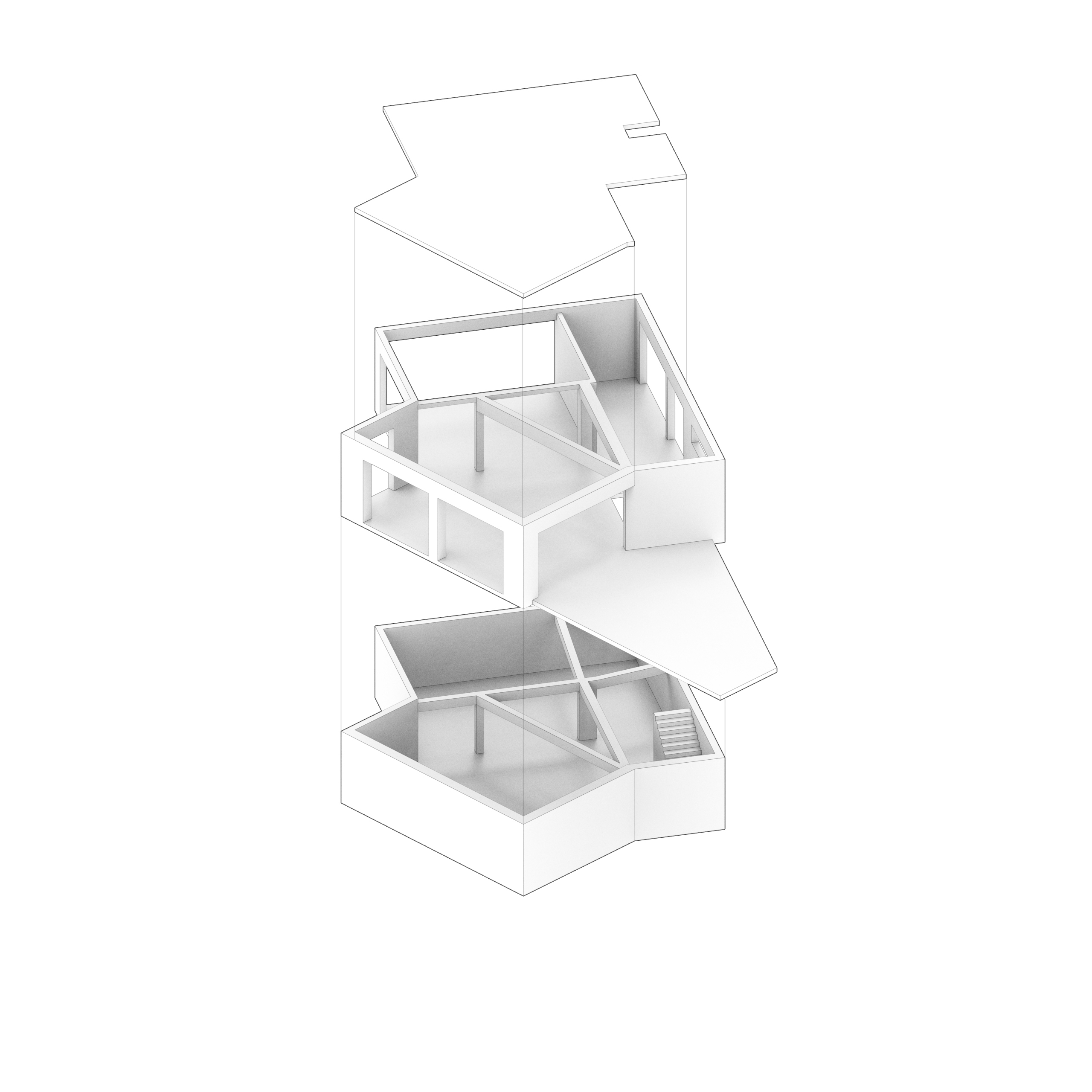

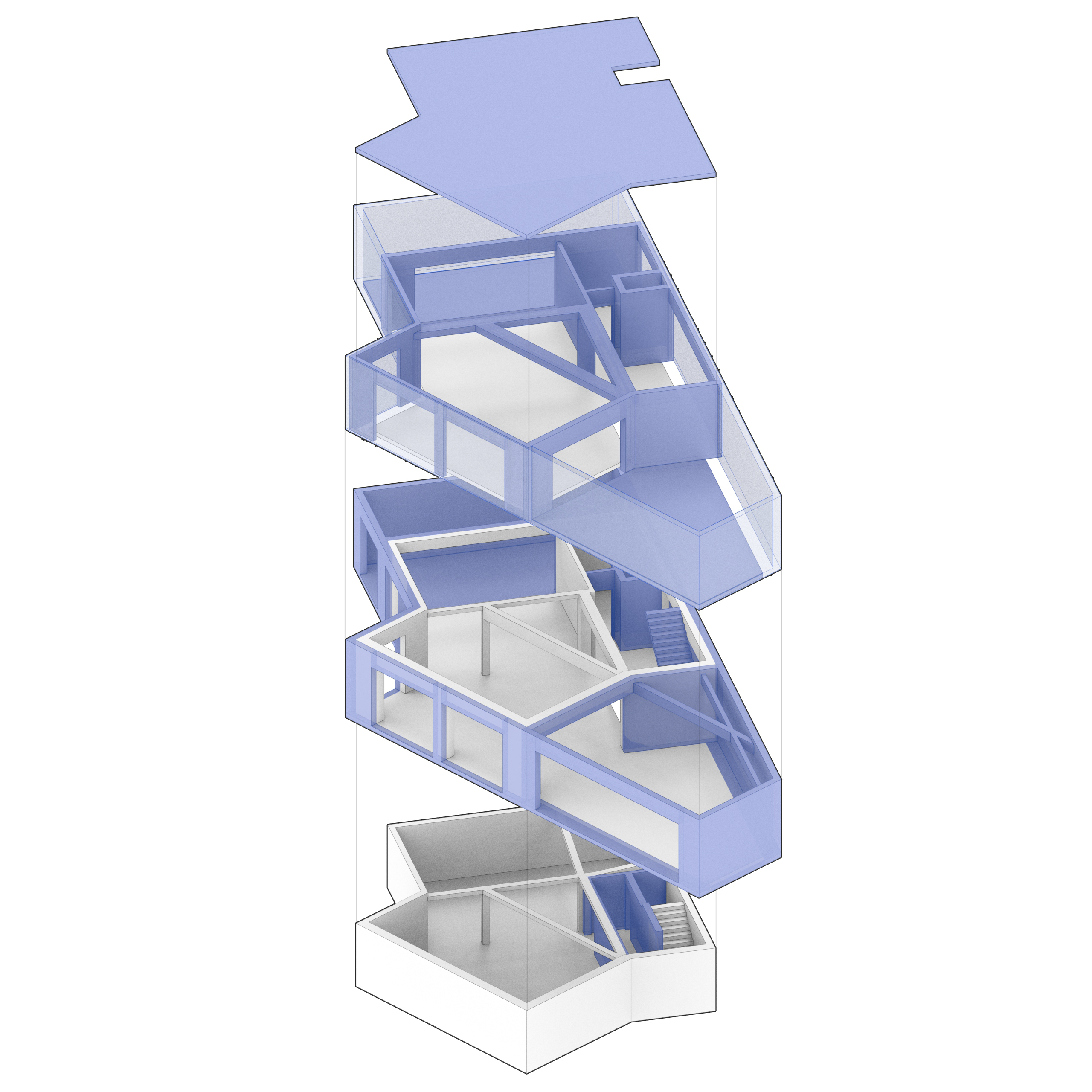

This Adaptive Reuse Project at the American School of Marrakech revolves around the transformation of a currently underutilized 250 sqm building into a dynamic Makerspace environment. This proposal seeks to revitalize the existing structure, which is presently used for storage and teaching purposes, by infusing it with a renewed purpose that aligns with the school's educational objectives. The primary goal is to create a space where creativity, innovation, and collaboration can flourish, not only among students and faculty but also within the broader local community of Marrakech.

The redesigned space features a flexible layout that can accommodate a variety of activities, including workshops, prototyping, experimentation, and collaborative projects. Dedicated areas are allocated for different disciplines such as woodworking, metalworking, electronics, textile, and 3D printing, each equipped with specialized tools and equipment to support hands-on learning experiences. Additionally, open collaboration zones are integrated, providing inviting spaces for brainstorming, group discussions, and project planning, equipped with whiteboards and presentation facilities.

A key aspect of the project is the integration of digital technologies to enhance the creative process and expand the possibilities for innovation. Furthermore, the Makerspace serves as a hub for community engagement and outreach, allowing for partnerships with local schools, universities, and community groups.

![]()

![]()

![]()

![]()

In terms of materiality, the project embraces a sustainable approach by incorporating locally sourced materials that not only reflect the cultural context of Marrakech but also contribute to environmental stewardship. The lower level of the building integrates adobe and red clay render, materials abundant in the region, known for their thermal mass properties. By utilizing these materials, the project capitalizes on their ability to absorb and store heat throughout the day, thereby minimizing the building's environmental footprint and enhancing its resilience to fluctuating temperatures.

Furthermore, the integration of polycarbonate on the upper floor allows for the maximum penetration of sunlight, harnessing natural daylight to illuminate interior spaces and reducing the need for artificial lighting. Simultaneously, it maintains privacy through its translucent properties, negating the need for additional window coverings that could impede daylighting.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

The redesigned space features a flexible layout that can accommodate a variety of activities, including workshops, prototyping, experimentation, and collaborative projects. Dedicated areas are allocated for different disciplines such as woodworking, metalworking, electronics, textile, and 3D printing, each equipped with specialized tools and equipment to support hands-on learning experiences. Additionally, open collaboration zones are integrated, providing inviting spaces for brainstorming, group discussions, and project planning, equipped with whiteboards and presentation facilities.

A key aspect of the project is the integration of digital technologies to enhance the creative process and expand the possibilities for innovation. Furthermore, the Makerspace serves as a hub for community engagement and outreach, allowing for partnerships with local schools, universities, and community groups.

In terms of materiality, the project embraces a sustainable approach by incorporating locally sourced materials that not only reflect the cultural context of Marrakech but also contribute to environmental stewardship. The lower level of the building integrates adobe and red clay render, materials abundant in the region, known for their thermal mass properties. By utilizing these materials, the project capitalizes on their ability to absorb and store heat throughout the day, thereby minimizing the building's environmental footprint and enhancing its resilience to fluctuating temperatures.

Furthermore, the integration of polycarbonate on the upper floor allows for the maximum penetration of sunlight, harnessing natural daylight to illuminate interior spaces and reducing the need for artificial lighting. Simultaneously, it maintains privacy through its translucent properties, negating the need for additional window coverings that could impede daylighting.